Springs Comfort and fatigue

The degree of discomfort we are prepared to accept from a pro automobile suspension depends largely on the vehicle and its purpose.

A racing driver will endure vibrations that blur his vision and vertical accelerations that jar his spine, yet he only mentions such things to the team manager if he has noticed a subtle change from the norm since such a change could indicate a flat spot on a tire or an impending transmission failure.

This same driver, however, will complain that his new sports car has a hard ride, even though by comparison with his racing car the sports car gives a ride like a feather-bed. In a sports car, most drivers will accept a relatively hard ride as a necessary adjunct to precise high-speed handling and safe fast cornering. In a large saloon, a similar ride would be considered intolerable.

Tolerance to vibration

The medical profession has been interested in the effects of vibration on the human body for many years. In particular, studies have been made to establish which particular frequencies are harmful and produce fatigue quickly in industrial workers.

Raynaud’s phenomenon, for example, is associated with high-frequency vibrations in the range 20-200 Hz from handheld power tools, while motion sickness is more likely to occur with very low-frequency vibrations in the range 0.1-0.5 Hz. As a broad guide, we can say that the human frame experiences fatigue most quickly when exposed to vibrations in the range 4-8 Hz.

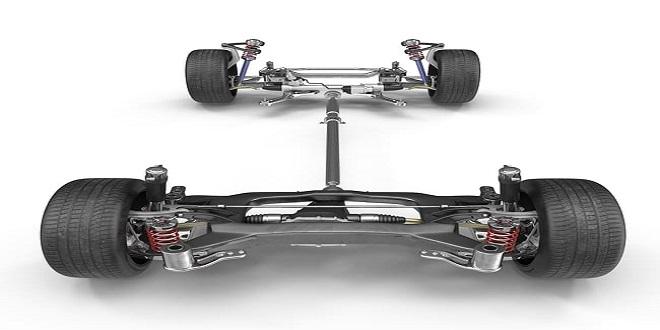

Spring design

A simple spring system is shown in Fig. 2.1. In the mean position, the force exerted by the coil spring P exactly balances the weight (or gravitational force) W of the mass M. If the mass is displaced by distance x, the spring force will increase to P + kx, where k is the stiffness or rate of the spring, i.e. the force per unit displacement.

In the displaced position the body of mass M, if released, will accelerate towards the mean position at a value of x. Since x is considered positive in a downward direction, this acceleration will also be positive. Conversely, if the body is displaced in an upward direction by an amount -x, the acceleration will be in the opposite direction.

prints can take a multitude of shapes: parallel coils, conical coils, torsion bars, spirals, disks, single leaves, and laminated leaves; there seems to be no end to the possibilities. One need not be confined to metallic materials.

They can be made of rubber or take the form of a gas container compressed by a piston or diaphragm. Today the most popular spring in use on automobiles is the coil spring with coils of identical diameter and spacing.

It is also convenient and certainly inexpensive to use a constant gauge from top to bottom. Such a spring usually gives a close approximation to a constant spring rate over its working range. If we compress it 10 mm and it exerts a force of F Newton’s compression to 100 mm will give a restoring force of 10F Newtons.

Last word

One can, of course, vary the spring gauge or the diameter of the coils to give a variable-rate spring, but our mathematical analysis would, at ‘this stage of our study, become very long and tedious if introduced such complexity.