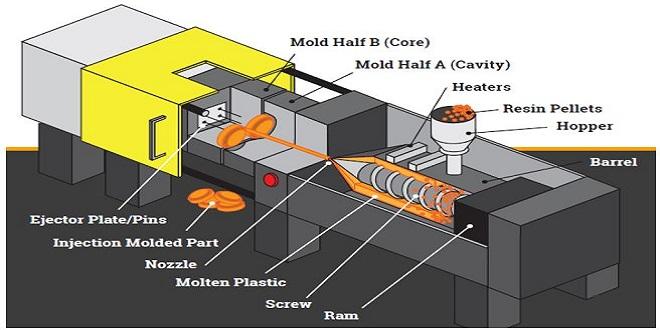

How Design Engineers Can Enhance Part Development of Tight Tolerances in Injection Molding

Tight tolerances are a known component of injection molding. This industry involves the production of high-functioning parts with slim margins of up to +/- .001 inches. However, business owners cannot develop the features independently but rely on expert product designers to create efficient ways of producing these tight tolerance injection molding parts.

Design is not only necessary in the initial stages of production but is vital when analyzing complications in part efficacy. If a consumer purchases a product that does not perform its function optimally, the structure must have a problem. The production of uniquely shaped products is the crucial goal of injection mold services. These shapes influence part performance. Therefore, the part’s structure and function complication require reference to the initial design to detect anomalies.

The best way for injection molding manufacturers to produce parts of high-standard efficacy is to collaborate with design engineers, who understand the relationship between structure and function. Design engineers should implement the following strategies to manage the tight tolerances involved in injection molding to promote the production of efficient parts:

- The design phase should start early

If you are an ambitious injection molding manufacturer, you should appreciate the significance of the design stage of the production process. Although some products undergo a straightforward production process using specialized machinery, some require specific designs and implementation to ensure accurate shapes for improved performance. Business owners should invest in expert product designers and design engineers who appreciate the product’s intended function and thus develop a specific form for product parts.

The design stage needs to start early. This time allowance is necessary to ensure that design engineers collect enough data about the product function. Thus, they develop a specific design approach to ensure the product gets the correct shape to boost its efficacy. Although business owners rush to production due to the excitement of beginning a new project, they should be wise to invest time into the design process to ensure no complications arise after production.

- Analyze complexity

Enhancing tolerance is the only way to ensure seamless injection molding. Tight tolerances occur when there is complexity in the structural design of a part. This complexity affects molding repeatability and might interrupt the tight tolerances involved in injection molding.

Design engineers should not forget to analyze a part’s risk of shrinking and warpage before beginning production. For this reason, business owners should hire capable design engineers who appreciate the role of implementing a design for manufacturability approach before starting production to save on costs that may develop due to delays and reworks coming from complex design production.

- Appreciate the environment where the part will function

It is beneficial for design engineers to understand the intended function of a part but also to appreciate the environment where the part will function. The environment where the part will spend most of its time will determine its fate. Moreover, the environment determines resin behavior. Design engineers have a lot of work to do to ensure seamless part production. The most significant task is ensuring capable parts’ production and maintaining injection molding tolerances. Therefore, business owners should inform injection molding manufacturers of specific product details that will influence design.

One way for design engineers to succeed in producing efficient parts for specific environments is to appreciate resin behavior. For example, a designer should evaluate the expansion coefficient to determine how a part will operate under various temperatures. Understanding the material of the parts will also distinguish their longevity. Therefore, designers should implement a comprehensive evaluation to develop the right products for specific functions.

Design engineers have a critical role in influencing the efficacy of manufactured parts in specific application settings. For this reason, business owners should invest in a trained and experienced team of design experts who understand the best strategies to handle the production of complex parts that will serve consumers well for a long time. However, it is also necessary for business owners to remember that other factors, including tooling, process design, and resin selection, influence injection molding tolerances of complex parts. Collaborating with a trusted injection molding partner will enhance the predictability of the design and production process to ensure satisfactory customer results for boosted company profit.