Custom Rapid CNC Plastic Milling

Plastic is frequently employed in today’s products. This page explains how it’s made and what a CNC milling plastic is.

CNC Milling Plastic

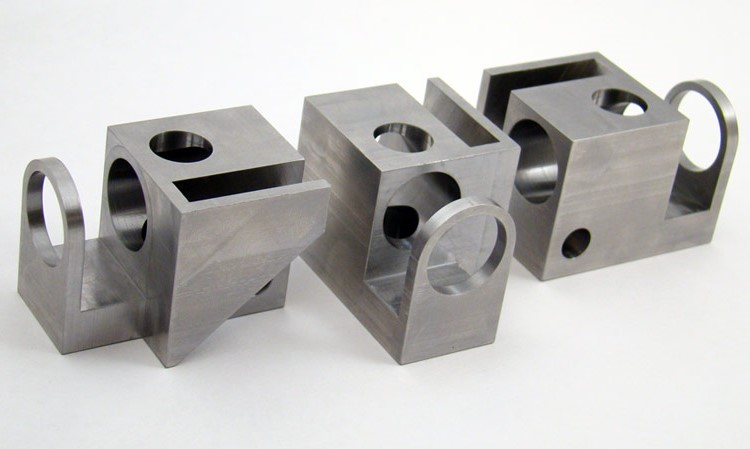

CNC milling uses a computer-controlled CNC router to mill materials. The design is imported into the CNC machine, then it’s programmed to make the cuts. The parts are made, removed, and checked.

CNC milling creates components or products using a CNC machine. CNC milling involves cutting a product or component from a piece of material, but 3D objects may also be manufactured. Digital models of components or final products are sent into CNC machines. The CNC machine’s cutting tool will cut an object block of material.

CNC plastics milling advantages

CNC-milled plastic is created using a CNC milling machine. CNC-milled plastic is employed in the aerospace and medical industries because of its robustness and low weight.

CNC machines mill thin plastic sheets. Molds are used to form tubes, pipelines, and connectors from the sheet. Durable, lightweight plastic may be CNC machined. It’s ideal for lightweight, robust medical and aviation equipment.

CNC plastic milling is inexpensive. It’s great for affordable medical gadgets. CNC milling plastic may be used to make things that are difficult or impossible to make from other plastics.

Conclusion

CNC milling is a way to produce plastic objects fast by directing a tool’s movement using a computer. If you understand the basics of plastics technology, you can make better decisions while making plastic components yourself. Contact AS PRECISION, who provides professional custom CNC milling services for your business.