Mechanical Seal Identification

Regularly, service experts bring us mechanical seals for replacement or repair. It does the same in reverse. The dimensions of the pump, the impeller, the suction, and the discharge are irrelevant. One may utilize a pump for a variety of purposes. In contrast to pumps, seals are often used just in a single circumstance. Since there are many different seal configurations used by different manufacturers, the pump model is insufficient.

To begin, seal part numbers are practical. The Elastomer, Seal Faces, and metal composition of a given seal are all denoted by a unique part number used by the industry’s leading manufacturers.

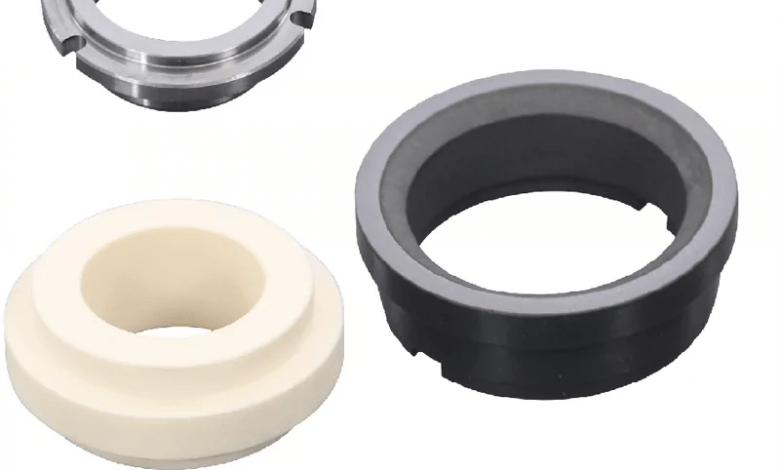

Even if the component’s part number is missing or has been worn away from use, it may still be possible to identify the part. Pick an elastomer with the lowest strength. It is useful to use deductive reasoning. In the beginning, have a look at the rubber pieces. Are they injure chemically, melted, brittle, or hard? If they are still pliable and in great condition after being treated with the elastomer, we may consider our mission accomplished. If not, we’ll have to switch to a different kind of elastomer. Elastomer may be narrowed down to a more manageable set by considering both temperature and use. Over 325 degrees Fahrenheit, Aflas or Viton, should be used. If the temperature is over 325 degrees Fahrenheit, a chemical compatibility table may be useful.

Now think about the faces of seals. If you’re not colorblind, it’s a piece of cake. The color white best describes ceramic sealing. Metals such as brass, bronze, or aluminum bronze provide the appearance of being used for seal faces. Silicon carbide is a gray and lightweight material. The materials ceramic and silicon carbide are closely linked. Grey or silver, tungsten carbide is a dense metal. Most seals’ heads are in the air, with the possible exclusion of coatings applied by spraying. They are uncommon because they are prone to failure.

It’s been observed that different seals use different methods to keep their faces pumped with energy, usually in the spring. There are a few different kinds of spring sets: single, multiple, and wave. The emergence of a rare wave. When there isn’t much space in the pump, one spring is used in 80% of all seal installations (water service). A non-spring? The bellows are made of metal. Despite their high cost, metal bellows are a necessary component of boiler feed pumps.

Metals are less important since they degrade over time. Standard seal materials include brass, bronze, stainless steel (types 304 and 316), and nickel. High-temperature Hastelloy is used in nuclear applications, whereas corrosion-resistant Monel is preferred for use in seawater.

Conclusion

You can find all you need to know about mechanical seals in Junty. Don’t hesitate to get in touch with Junty if you’re thinking about purchasing mechanical seals. Improved goods and sound guidance are what we have in store for you.